geem

Well-known member

Last edited:

It's a real shame. Rod was a pioneer of lithium on boats. A fountain of knowledge. It was a very informative video but he did slag off the main guy at Winston for being a crook."This video has been removed by the unloader"

You can still view it on the American cruisers forum"This video has been removed by the unloader"

https://www.youtube.com/watch?v=TkyF976hAxoI am on 27.7 bulk and 26.4 float on 24v batteriesFantastic, thnx for link, glad i saw it before he took it down. Wonder why, possibly a tiny bit libellous towards Winston..

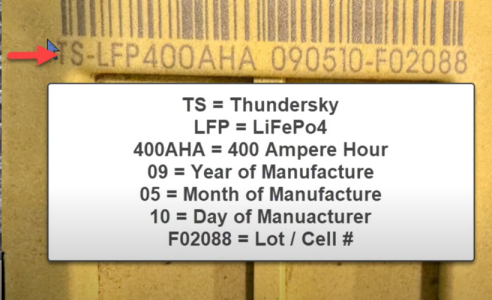

So 15 years use, hundreds for discharges to 0%,

"As you will learn in the video, I stopped counting cycles at 2150. Because this bank was an experimental pack, I did not recharge until at least 80% DoD. Today at 15 years these cells can still deliver 413.4Ah! This pack was never charged beyond 13.8V at .4C. I never had balance issues and never had capacity issues . "

View attachment 176763

Lead's dead, baby!

Very happy I ended up doing the same limits as he did, never above 13.8v & "float" a bit lower @ 13.3v

His cells are Winston.I had no problem watching the video - except I found the accent difficult to decipher.

This latter was important to me as I could not Devine which, or whose, batteries he was using - mainly because I'm not familiar with Lithium battery manufacturers. I did recognise Winson - whom and which he damned - but has been heavily supported here.

One take away - my interpretation - build you own battery - because if you buy an off the shelf battery you have no idea, or may have no idea, which cells they use and whether the cells you are buying are from someone he says are crooks.

He was using a JK BMS. The vid focus was on the cells - not the BMS. He only mentioned the JK BMS in passing.

His charge and float voltages are much lower than the charge and float voltages quoted by almost anyone else, see Geem's post above, post No 4. He is very comfortable running his battery bank down to near zero. 0%, but qualified this later in the vid by suggesting if you are uncomfortable then 10% or 20% is fine. Freezing conditions remain an issue, which presumably is why some batteries are marketed with built in heaters.

He had built a compression 'case' which he seemed to emphasise was essential or critical. He said it was built from aluminium plate - and if he wants to compress the cells then it would need to be pretty robust aluminium which would possibly be the 7000 alloy series, specifically 7075 T6 temper (about 520 MPa) - I think used for the MacBooks and iPads. He did not mention why aluminium, there is steel plate with much higher tensile strength, allowing use of much thinner plate (as used in the automobile industry). Aluminium would be lighter and may be better in the marine environment (though batteries should not be exposed to water and you could paint the HT steel) - and he prefaced the vid saying he had had a yacht and that was part of his motivation. I think he said, I've only watched the vid once, the cross rods we're also aluminium (you can buy the plate 'off the shelf' from most aluminium stockists - though I'm not sure of the rods, you can buy HT steel tube). Compression cases have not enjoyed much of an airing here - and from memory they seem to have been made from ply - which is hardly robust. But he did emphasise the critical need of the compression case. For thin HT steel look at the SSAB website, say their Hardox range.

What was interesting to me was that his battery bank was being used in a terrestrial application (despite the constant criticism I have received for doing 'exactly' the same thing).

What I missed most was - who made his cells? and/or though he did no recommend, but repetitively damned some,

Which cells did he approve?

Jonathan

Rod had a stroke 2 years ago. Little use in his left arm and trouble with speach.I had no problem watching the video - except I found the accent difficult to decipher.

This latter was important to me as I could not Devine which, or whose, batteries he was using - mainly because I'm not familiar with Lithium battery manufacturers. I did recognise Winson - whom and which he damned - but has been heavily supported here.

One take away - my interpretation - build you own battery - because if you buy an off the shelf battery you have no idea, or may have no idea, which cells they use and whether the cells you are buying are from someone he says are crooks.

He was using a JK BMS. The vid focus was on the cells - not the BMS. He only mentioned the JK BMS in passing.

His charge and float voltages are much lower than the charge and float voltages quoted by almost anyone else, see Geem's post above, post No 4. He is very comfortable running his battery bank down to near zero. 0%, but qualified this later in the vid by suggesting if you are uncomfortable then 10% or 20% is fine. Freezing conditions remain an issue, which presumably is why some batteries are marketed with built in heaters.

He had built a compression 'case' which he seemed to emphasise was essential or critical. He said it was built from aluminium plate - and if he wants to compress the cells then it would need to be pretty robust aluminium which would possibly be the 7000 alloy series, specifically 7075 T6 temper (about 520 MPa) - I think used for the MacBooks and iPads. He did not mention why aluminium, there is steel plate with much higher tensile strength, allowing use of much thinner plate (as used in the automobile industry). Aluminium would be lighter and may be better in the marine environment (though batteries should not be exposed to water and you could paint the HT steel) - and he prefaced the vid saying he had had a yacht and that was part of his motivation. I think he said, I've only watched the vid once, the cross rods we're also aluminium (you can buy the plate 'off the shelf' from most aluminium stockists - though I'm not sure of the rods, you can buy HT steel tube). Compression cases have not enjoyed much of an airing here - and from memory they seem to have been made from ply - which is hardly robust. But he did emphasise the critical need of the compression case. For thin HT steel look at the SSAB website, say their Hardox range.

What was interesting to me was that his battery bank was being used in a terrestrial application (despite the constant criticism I have received for doing 'exactly' the same thing).

What I missed most was - who made his cells? and/or though he did no recommend, but repetitively damned some,

Which cells did he approve?

Jonathan

He didnt dam the cells just the guy running Winston

Even if you were not to bother with compression, and if you ran the cells up to 14.4V every day, and ran them back down to 0% every night, they would still last such a long time it’s not even worth thinking about.

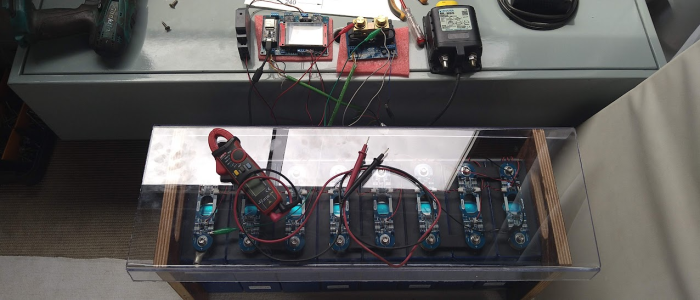

My take is - I'm ignorant and weigh up the advice given. In the video mention is made the cells do swell, and I think the suggestion was this is not advantageous. Geem and Sea Fever aka Kelpie have both mentioned 'boxing' the cells and using threaded rod to tighten the 'box'. The cells need to be clamped together anyway as you cannot rely on the bus bars - which only retain the cell tops.

I did note in the video the cells are only retained, compressed, on the sides, not the ends (nor top and bottom). Geem's photos in one of his earlier threads had the same arrangement, just retained on the sides. I found this 'interesting'.

Why not retain them tightly - but taking opportunity here to define how 'tight' is tight.

If the cells are going to have the long life being indicated - a decent professional 'clamp' seems appropriate ' just to keep the battery (aka collection of cells) secure.

All of these recommendations need clarification where possible and like the charging/float levels - modification in the light of developing knowledge.

Do you have any evidence that this has been an issue?

Jonathan

No definitely not. Under compression is worse than over compression. I read a good article some time ago by an engineer from Eve who said that.I bet there have been more cells damaged from over compressing than under compressing them.

No definitely not. Under compression is worse than over compression. I read a good article some time ago by an engineer from Eve who said that.

I think for the purposes of installing cells in a DIY on a boat, you need enough compression to ensure cells are held firmly. This then gives you the opportunity to hold the battery in place. Cells that are under compressed run the risk of rubbing between cell cases. Cells need separators to keep the cases electrically insulated

My Catl cells specified the compression required for cycle life in the datasheet.As I said, barely any pre made batteries are ‘compressed’ in the DIY sense of the word. And they out number diy packs by many orders of magnitude.

I agree re making sure the cells cannot rub, hence why most manufacturers use strapping tape to lock them together.