Neeves

Well-known member

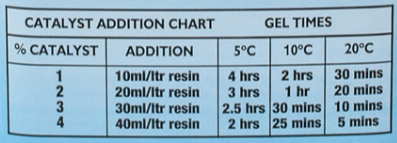

&-8 weeks ago made up some epoxy at the 2:1 instruction on the label. I wetted out some fibre glass. It did not set off. We have been away for 6 weeks - some of it has still not set off. It has been cold in Sydney, its winter here and night time temps get down to 5 degrees, and as my workshop is 'underground' it is cold.

What to do?

I am reluctant to scrap it all. I have thought of over coating with a new layer of resin, this might (or might not) set off - but even if it does set off the impregnated glass will still be encased in 'sticky' (to the touch - it does not stick to your fingers) low strength resin. I can leave it, put it in the sun, just be patient.

Why it did not set off...? Its been cold, the resin is not fresh, at a 2:1 mix even an idiot would not get it wrong.

Suggestions, to remedy the issue.

Jonathan

What to do?

I am reluctant to scrap it all. I have thought of over coating with a new layer of resin, this might (or might not) set off - but even if it does set off the impregnated glass will still be encased in 'sticky' (to the touch - it does not stick to your fingers) low strength resin. I can leave it, put it in the sun, just be patient.

Why it did not set off...? Its been cold, the resin is not fresh, at a 2:1 mix even an idiot would not get it wrong.

Suggestions, to remedy the issue.

Jonathan