jon and michie

Well-known member

Right as there has been much debate on this subject that seems endless and is like marmite either a branded make or unknown Chinese version - I thought I would post my install that I planned over lockdown period and researched before jumping in.

As a sort of foreward to this post This is a Chinese heater that I bought on ebay for £89 and I purposely got it in a aluminium casing was installed in such a way that if it ever failed all that would be required is to just remove the heater unit and install the new one

Here goes

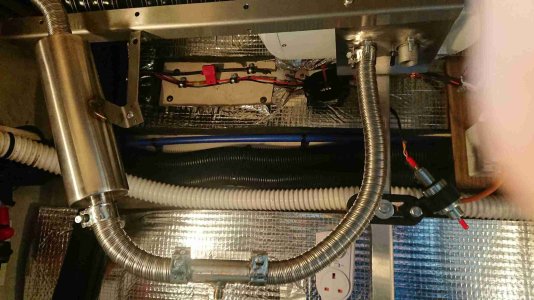

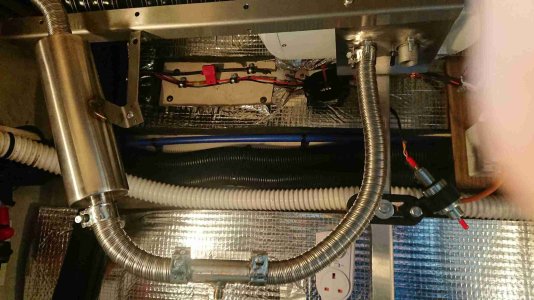

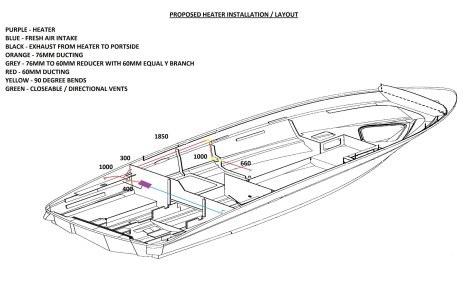

Here was part of my planning with ducting measurements - Because of the space the heater had to be suspended - This was done using high temperature gasket paper to mount the custom bracket (which I had 2 lying around) This was to stop any transfer of any heat to the above GRP.

The Hull Skin fitting was fitted again with High Temp gasket paper and I fabbed up a backing plate for it to be bolted to - the fitting was well above the water line and had high temp sealant added to protect the outside grp from water ingress.

The Ducting was 76mm diameter (the planned drawing says to be reduced but I stayed with the one size) 2 ply silicone which could take up to 260 degrees C - the Ducting insulation I made up from High teperature insulation rated at something like 2000 degrees C

As a sort of foreward to this post This is a Chinese heater that I bought on ebay for £89 and I purposely got it in a aluminium casing was installed in such a way that if it ever failed all that would be required is to just remove the heater unit and install the new one

Here goes

Here was part of my planning with ducting measurements - Because of the space the heater had to be suspended - This was done using high temperature gasket paper to mount the custom bracket (which I had 2 lying around) This was to stop any transfer of any heat to the above GRP.

The Hull Skin fitting was fitted again with High Temp gasket paper and I fabbed up a backing plate for it to be bolted to - the fitting was well above the water line and had high temp sealant added to protect the outside grp from water ingress.

The Ducting was 76mm diameter (the planned drawing says to be reduced but I stayed with the one size) 2 ply silicone which could take up to 260 degrees C - the Ducting insulation I made up from High teperature insulation rated at something like 2000 degrees C

Attachments

-

layout of ducting.jpg193.4 KB · Views: 72

layout of ducting.jpg193.4 KB · Views: 72 -

DSC_1705_4_11zon.jpg171 KB · Views: 69

DSC_1705_4_11zon.jpg171 KB · Views: 69 -

DSC_1711_5_11zon.jpg190 KB · Views: 58

DSC_1711_5_11zon.jpg190 KB · Views: 58 -

Bracket Installed 2_2_11zon.jpg188.9 KB · Views: 60

Bracket Installed 2_2_11zon.jpg188.9 KB · Views: 60 -

Bracket Installed 1_1_11zon.jpg137.5 KB · Views: 57

Bracket Installed 1_1_11zon.jpg137.5 KB · Views: 57 -

Through hull fitting 2_5_11zon.jpg169.2 KB · Views: 56

Through hull fitting 2_5_11zon.jpg169.2 KB · Views: 56 -

exhaust fitting Gasket 1_11_11zon.jpg188.5 KB · Views: 56

exhaust fitting Gasket 1_11_11zon.jpg188.5 KB · Views: 56 -

Exhaust fitting backing plate_10_11zon.jpg180.7 KB · Views: 54

Exhaust fitting backing plate_10_11zon.jpg180.7 KB · Views: 54 -

Ducting_8_11zon.jpg154.7 KB · Views: 57

Ducting_8_11zon.jpg154.7 KB · Views: 57 -

Duct Insulation_9_11zon.jpg167.1 KB · Views: 62

Duct Insulation_9_11zon.jpg167.1 KB · Views: 62

Last edited: